| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size: |

300mm*200mm*300mm |

| Application: |

Peanut,Sesame |

| Type: |

Pressing Machines |

| Appearance: |

Vertical |

| Press Materials: |

Peanut,Sesame,Beans,Almonds,Walnuts |

Product Description

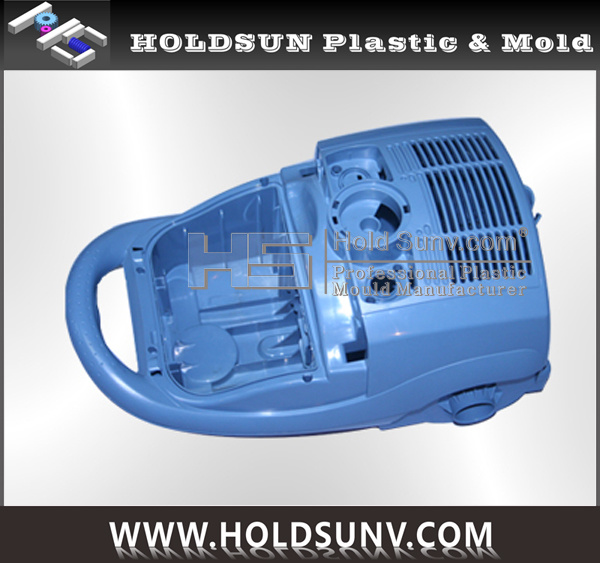

Home appliances mould and part

Holdsun has been in Home Appliance Mold & Parts manufacturing over 15 years, we have rich experience for this field and cooperate with well-known companies such as TCL, Haier, ZhongNon, Wal-mart and provide them both mold and plastic injection parts of TV set, water heater, mini oil press machine, air purifier, vacuum cleaner, etc The Home Appliance parts plastic molds are 35% of Holdsun Mold total mold sales, we adopt high quality steels for mold and advanced injection machine that with robot hand to ensure our product quality and efficiency.

Base on your Household Appliance product, or TV shell mould needs, we can design electrical home appliances mould, Television shell mold for you. Our mold technology is very professional. Welcome to order all kinds of customized Home use Appliance mold products.

|

Item name.: |

Plastic Parts Mould Solutions |

|

Plastic Mold Description: |

Trademark: HOLDSUN

Manufacture Equipments: CNC, EDM,Milling,Wirecut,Lathe Machine,Grinding Machine,Drilling Machine,StreetCranes,QC Equipments-3D CMM & 2D,Projector,Haitian Plasti

Mold Base: HASCO,LKM, DME, FUTABA,etc.

Mold Cavity: Single,Mult,Family

Mould Components: DME

Molding Material: ABS,flame-retardant ABS,HIPS,flame-retardant,PS,HDPE,PMMA,PC,PVC, PP,TPR and TPU.

Color: Transparent,Solid Color,According to your requests

Surface Finish: Matt,Textured,Glossy or Mirror Polished,Printing,Silk screen,Chrome Plating,ect.

Design & Program Software: Solidwork,Moldflow,CAD/CAM/CAE,UG,Pro-e,PowerMILL,etc.

Mold Material: 1.2344,S7,H13,P20,718,718H,2738,738H,NAK80,SKD61,E420,etc.(for reference only)

Main Cavity/Core Material: ASSAB from Sweden/DAIDO from Japan, AUBERT&DUVAL

Mold Life: 300,000-1,000,000cyces,According to your requests.

Runner: Cold,Hot Runner,such as YUDO,MASTER,SYNVENTIVE,etc.

Lead Time to T1 Sample: 4~8weeks

Lead-time for Production: 1~2weeks

Quality: ISO 9001:2000,TS16949

Precision: 0.005mm

Packing: Wooden Case Packing or According to Your Requirement.

Service: OEM & ODM Service. |

|

Brief Introduction Of Our Company: |

Holdsun Company specializes in tight tolerance custom mold and injection molded plastic products.Call Us today!Product customized and online services of every kind can be yours now! As a collection development, production and trading enterprise, not only we have our own design & products, but also we can develop your idea form initial concept to final product. We have experts ready to assist with design consultation, in-house fulfillment produce, co-packing,quality control, global logistics and at competitive prices to suit your needs. |

|

Competitive Advantages: |

1. One-Stop Service, In-house tooling design and manufacturing

2. Flexible manufacturing quantities.

3. Custom R&D program coordination 4. Over 15 years experience, Application expertise.

5. Diversified rich experienced skilled workers.

6. Continuance service and support.

7. Advanced Produce Equipments

8. Strict Quality Control, 100% incoming, 100% online & 100% outgoing check

9. ISO9001:2000,ISO/TS 16949:2002, British SGS QS9000 Certification Manufacturer, Made-in-China.com Gold Memeber & Aduited Supplier

10. High quality, Low price, Prompt delivery, Superior service

11. OEM/ODM are Welcome. |

|

Our Product Range: |

1. Household Appliances parts & Mould

2. Automobile Mould & parts

3. Office Equipment parts & Mould

4. Medical Appliances parts & Mould

5. Plastic Baby Toys parts & Mould

6. Ribbon Series & accessories

7. Double color Mould & Over Mould

8. Clear parts & mould

9. Pipe Fitting Mold

10. Precision Die Casting parts & mould |

|

Equipments: |

CNC Milling Machine: 5 sets (Taiwan)

EDM Machine: 5 sets (Mitsubishi )

Slow-feeding Wre-Cut Machine: 2sets (FANUC and Mitsubishi )

Wire cutting machine: 3 sets

Milling Machine: 4 sets

Grinding machine: 2 sets

Lathe Machine: 1 sets

Drilling Machine: 1 sets

Street Cranes: 7sets

Injection Machine: 120T/200/T/280T/380T/800T/1300T (Total: 40sets) |

|

Contact Details: |

Address:

Licun Industrial Zone, Xiegang town, Dongguan, Guangdong, China

Contact Numbers:

Phone:+86-134-3409-2614

Website:

http://www.holdsunv.com

Other Homepage Address:

http://hs-plastic.en.made-in-china.com

Key Contact:

Daisy Ng ,Charles Wong |

|

If you can`t find your desired items in our website, please contact us. We will contact you in 24 hours. Everything we do is for your satisfaction! |

Holdsun Industrial Co., Ltd. Was founded in Oct 1996, Holdsun means they will use their strength, wisdom to be loyalty to everyone, and open-mindedness like sun to accommodate new friends and old friends from worldwide.

Our factory lines in Dongguan, Guangdong, China, covers 10, 000 square meters, have 200 workers, and owns hundreds of delicate manufacturing equipments and quanlity control devices. We specailize in product research and development, rapid prototype making, Tooling, manufacturing and assembly that provide one-stop service for our customers.

We have strong engineering team for product research & development: 6 experiences mechanical engineers, 3 of them over 20 years experiences; 3 electrical engineers, 2 of them with over 20 years experiences; 1 industrial designer with over 6 years experiences.

We build plastic injection tooling, stamping die, die casting, blow molding, hydroforming die in house. Forming plastic parts and metal parts in house, metal parts and plastic parts surface treatment in house, assembly consumer products and electrical products in house. Not only we have tooling, injection production line, but also have advanced test equipments, and assembly, silk-screen, oil painting etc. To support one-stop service for our customers' Production and research our new products. With high quality & superior service, we gain customers satisfaction and we will work toward high quality, competitive price, prompt delivery as always to improve our customers and ourselves development.

Scope we specialize and focus:

1. Product Research & Development

2. Tooling (including: Plastic Injection Mould, Die Casting Mould, Stamping Mould, Blow Mould, Forming Mould, etc.

3. Plastic & Metal Parts

4. Electronic parts

5. Silk Screen and Painting

6. Product Manufacturing & Assembly

7. Shipping or Air Transportation

"The molds you made were nice, and injection produce was smoothly, which highly improve our efficiency. And we have more time to focus on the important stuff! " _____Sina Jalili, Brazil, Manager