| Prod Model: |

STK-P1160 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Finish: |

Color Painting, Texture, Silk Printing |

| Certificate: |

FDA, RoHS |

| Mould Leadtime: |

3-6 Weeks |

| Mould Life: |

100, 000-1, 000, 000 Shots |

| Machine: |

80 Ton to 800 Ton |

| Drawings: |

CAD, Cam, Cae, Solid Works, Caxa, Ug |

| Surface Finish: |

Powder Coating, Silk-Printing, Laser Etching, etc |

| Usage: |

Auto Parts, Medical Appliance, Electronies |

| Raw Material: |

PP, ABS, POM, Nylon, PC |

| Applications: |

Electronics, Audio Parts, Acoustic Parts |

| Boiled Egg Number: |

1-5 |

| Layer Number: |

Double Layer |

| Housing Material: |

Plastic |

| Certification: |

CE |

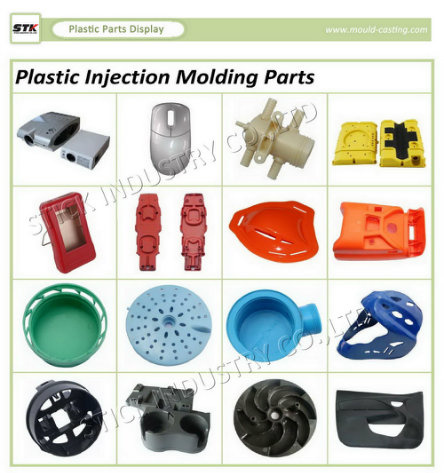

Product Description

Plastic Injection Solution: u Precision Injection Molding: From design consultancy & prototype tooling to high-volume world-class productionu Parts are widely used: Industrial, Automotive, Electronics & Medical Technical Skills - Development, Design Skillsl Design Consultation & Assistancel Pro/E, CAD/CAM/CAE including Solid Works(TM) and mold flow analysisl Material Selection Assistancel Quick turn-around prototype supportl Secondary Operations including machining, welding & assemblyMolding - High Precision, High Concernl Plastic Decorating: In-Mold Decorating (in-mold labeling), pad printing & hot stampingl 40 Molding machines from 80TONS to 1400TONSl High precision molding from medical to fiber optics components Secondary Operations - Value Added Servicel Pad Printingl Sonic Weldingl Assembly & Packaging

Injection Molding Capabilityu Material: PA, PA6, PA+FG, ABS, FR ABS, POM, PC, PS, PP, PVC, TPR, TPU, TPE, HDPE, PMMA etc.u Mold Cavity: Single or Multi-cavity u Mold Base: LKM or Equivalent Standard mold baseu Core Steel: NAK80 prehardened steel, 718, 718H, P20, S136 etc.u Injection Machine Size: 40sets range from 80TONS to 1400TONSu Max Mold Size: 1500mm x 1300mmu Product Unit Weight: From 0.1gram to 10,000gramsu Tooling Lead-time: 3-7 weeksu Production Lead-time: 2-4 weeksu Mold Life: 50,000shots to 500,000shotsu Surface Treatment: Chrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc.

| Material Name | Features | Applications |

| PP | Lightweight, Heat Resistance, High Chemical Resistance, Scratch Resistance, Natural Waxy Appearance, Tough and Stiff, Low Cost | Automobile (Bumpers, Covers, Trim), Bottles, Caps, Crates, Handles, Housings. |

| POM | Strong, Rigid, Excellent Fatigue Resistance, Excellent Creep Resistance, Chemical Resistance, Moisture Resistance, Naturally Opaque White, Low/Medium Cost | Bearings, Cams, Gears, Handles, Plumbing Components, Rollers, Rotors, Slide Guides, Valves |

| PC | Very Tough, Temperature Resistance, Dimensional Stability, Transparent, High Cost | Automobile (Panels, Lenses, Consoles), Bottles, Containers, Housings, Light Covers, Reflectors, Safety Helmets and Shields |

| PS | Tough, Very High Chemical Resistance, Clear, Very High Cost | Valves |

| ABS | Strong, Flexible, Low Mold Shrinkage (Tight Tolerance), Chemical Resistance, Applicable for Electroplating, Naturally Opaque, Low/Medium Cost | Automobile (Consoles, Panels, Trim, Vents), Boxes, Gauges, Housings, Inhalers, Toys |

| PA6 | High Strength, Fatigue Resistance, Chemical Resistance, Low Creep, Low Friction, Almost Opaque/White, Medium/High Cost | Bearings, Bushings, Gears, Rollers, Wheels |

| PA6/6 | High Strength, Fatigue Resistance, Chemical Resistance, Low Creep, Low Friction, Almost Opaque/White, Medium/High Cost | Handles, Levers, Small Housings, Zip Ties |

| PBT, PET | Rigid, Heat Resistance, Chemical Resistance, Medium/High Cost | Automobile (Filters, Handles, Pumps), Bearings, Cams, Electrical Components (Connectors, Sensors), Gears, Housings, Rollers, Switches, Valves |

| PVC | Tough, Flexible, Flame Resistance, Transparent or Opaque, Low Cost | Electrical Insulation, Household wares, Medical Tubing, Shoe Soles, Toys |

| HDPE | Tough and Stiff, Excellent Chemical Resistance, Natural Waxy Appearance, Low Cost | Chair Seats, Housings, Covers, Containers |

| PMMA | Rigid, Brittle, Scratch Resistance, Transparent, Optical Clarity, Low/Medium Cost | Display Stands, Knobs, Lenses, Light Housings, Panels, Reflectors, Signs, Shelves, Trays |

Injection Molding Capability

u Material: PA, PA6, PA+FG, ABS, FR ABS, POM, PC, PS, PP, PVC, TPR, TPU, TPE, HDPE, PMMA etc.

u Mold Cavity: Single or Multi-cavity

u Mold Base: LKM or Equivalent Standard mold base

u Core Steel: NAK80 prehardened steel, 718, 718H, P20, S136 etc.

u Injection Machine Size: 40sets range from 80TONS to 1400TONS

u Max Mold Size: 1500mm x 1300mm

u Product Unit Weight: From 0.1gram to 10,000grams

u Tooling Lead-time: 3-4 weeks

u Production Lead-time: 2-4 weeks

u Mold Life: 50,000shots to 500,000shots

u Surface Treatment: Chrome Plating, Silk-Printing, Laser Etching, Texture, Color Painting, etc.

Ms Ivy Lo

XIAMEN STICK INDUSTRY CO., LTD

Unit 05C,5th Floor,Hai Fu Business Center,

A 597 Shi Shui Road,Xiamen,China. Post Code:361008

Pho: (86)592-5209671, Fax: (86)592-5209672

Web: www.stickindustry.com www.mold-custom.com

We believe that the best way to ensure our success is by providing our customers consistent quality in a timely fashion and at a fair price.

Stick Industry was established in 2004, with factory located in Haicang district, Xiamen city, South East of China. The company has been in business for over 10 years, beginning as a small plastic mold and die casting mold workshop growing into an industrial leading, multi-plant molder with factory size over 10000 square meters and employees about 150.

Conveniently located in the south of China, our ISO 9001-2000 Certified facility economically services markets throughout the world including USA, Russia, Canada, Mexico, Brazil, Germany, Spain, Italy, Poland etc

In addition to outstanding growth in our die cast and injection molding department, our secondary machining operations have continued to grow to meet the varied needs of our customers, including: Drilling, tapping, turning, boring, milling, sanding, shot blasting, vibratory finish, and more.

From concept to final production, from mechanical and electronic design to components sourcing, and from prototype manufacturing to mold design, our engineer team can jump in at any stage to complete your valuable project on time.

Our service include: Moulds, plastic injection molding, Aluminum/Zinc Die casting, CNC Machining, Sheet Metal Forming, Surface Treatments, Assembly and packaging.

We will pay great attention to your any question or enquiry.

If any questions, please feel free to contact us at any time.

Tel: 86-592- 5209671

Fax: 86-592- 5209672

Ms. Anna Lin

Website: Www. Stickindustry. COM / www. Mould-casting. COM